-

Mobile Version

Scan with Mobile

- Member Center

Vacuum Brazing

XXXXXX

所属工业分类:

BRAZING SHEETS#ltd#REFRIGERATION INDUSTRY#ltd#HEATING AND SANITARY WARE INDUSTRY#ltd#Refrigeration-industry#ltd#Heating-industry

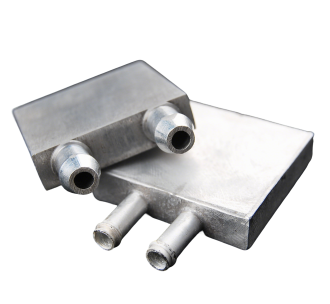

Vacuum brazing is performed in a controlled vacuum environment that isolates the workpieces from air and impurities, ensuring clean and precise metal joining. The process produces oxidation-free and pore-free joints with strength comparable to that of the base material, while eliminating the need for complex post-weld cleaning. It is particularly suitable for precision components made of stainless steel, titanium alloys, and high-temperature alloys. Vacuum brazing is widely used in applications with stringent quality requirements, such as aerospace engine components, semiconductor equipment chambers, and medical precision instruments.